Overview

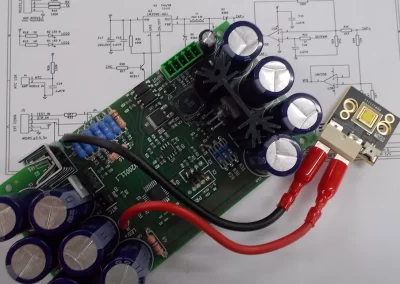

The project starts from the need to increase build speed of 3D models in laser resin stereolithography. Stereolithographic resin printers are normally based on monomodal diodes; this allows to have a small diameter and very well controllable spot thanks to the good quality of the source beam. On the other hand, this solution is intrinsically limited in power: the physical conformation of a monomodal diode does not allow to generate safely and reliably more than about 100-200mW of coherent radiation. A multimodal diode source has therefore been developed since these components reach powers of an order of magnitude larger than monomodals although at the expense of reduced beam quality. The development consisted in identifying and testing a multimodal component suitable for the application and developing a suitable beam delivery optics. The system gets acceptable spot, both in terms of size and spatial distribution of energy.

Development activity

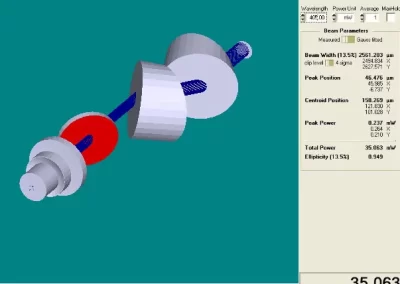

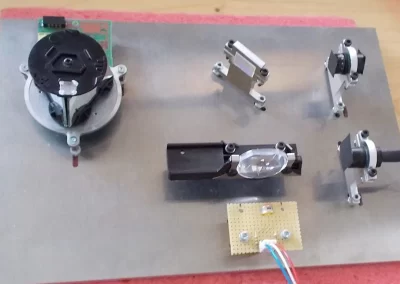

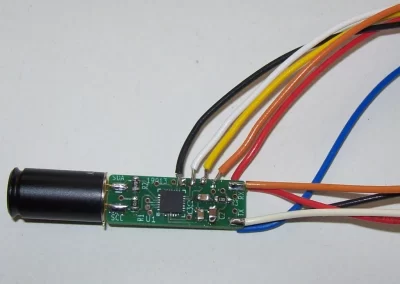

The research and development activity started from the analysis of some component of various suppliers (Opnext, Sony, Nichia); an extended simulation based on diodes parameters has carried out. Successively we designed a beam delivery optics based on a collimator and an anamorphic system to obtain a circular section collimated beam. Various solution has been evaluated to get different spot diameter (“waist” ). This diameter has been calculated and simulated in Gaussian optics, so as to predict both size and energy distribution profile within the spot. The results were also calculated taking into account the f- theta lens characteristics of different commercially available scanning systems. A prototype optics was developed for a practical test on a stereolithographic system to identify the appropriate components and verify that the optics meet the specifications and expectations.

Results

The system obtain a beam quality with M- squared values between 2.5 and 4. Quality is lower than typical values of 1,2-1,5 for monomodal diodes but still is sufficient in most applications. The beam delivery optics uses only commercial components avoiding the need of custom optics that involve demanding delivery times and costs. Thanks to the higher power and the increased spot diameter, while maintaining a uniform energy distribution within the beam, it has been possible to increase, by a factor of 4-5, the growth rate of models in stereolithography.