General information and use

The project consist on developing a probe to detect the temperature of food products directly on processing lines. In particular, the proposed problem is to measure the temperature of dough directly in the mixer tank.

State of the art: immersion thermometers are currently used which are unsuitable for measuring uneven and moving solid mass; standard industrial infrared thermometers that don’t have precision and features suitable for food processing.

Goal: develop a remote temperature reading probe suitable for processes that require high precision in temperature control.

Research and development steps

The steps followed are as follows:

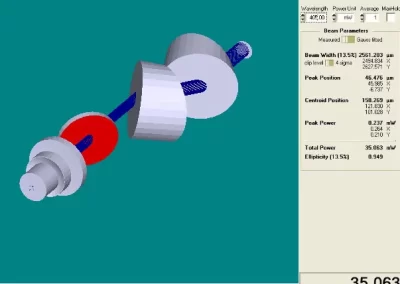

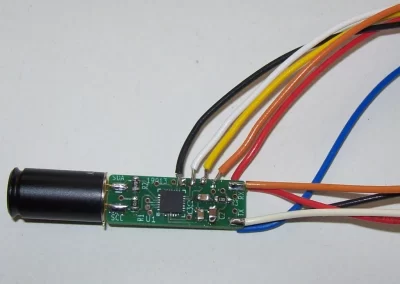

- Identification of a precision sensor, used in medical field for body temperature measurement, which has the necessary resolution and reliability.

- Measurement test on the mixer verifying the problems related to uneven temperature of the mass and the different temperature of the metal tank.

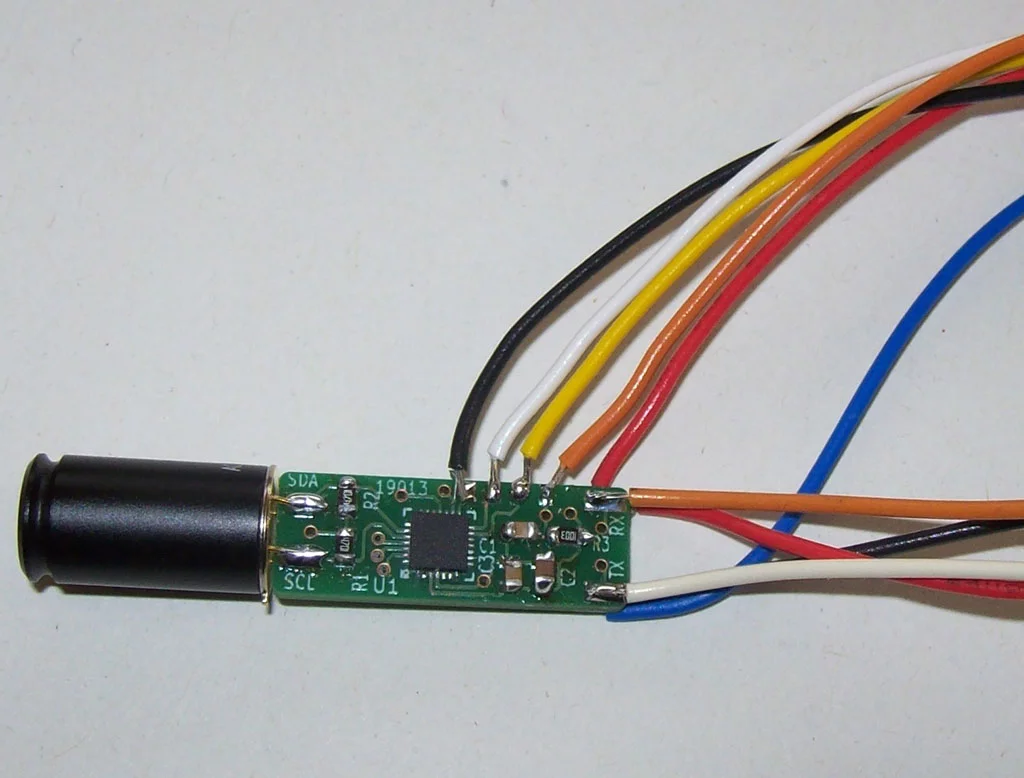

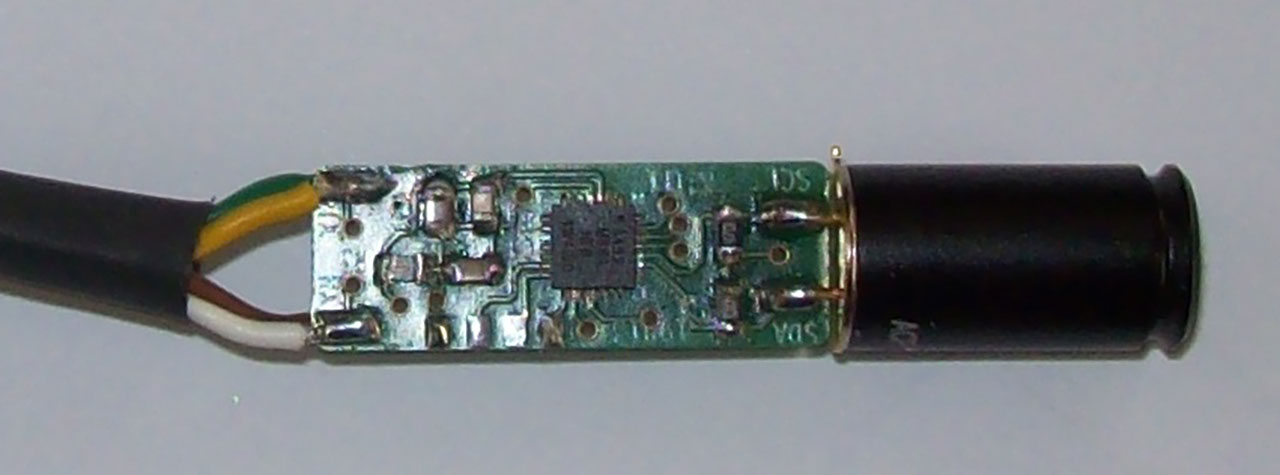

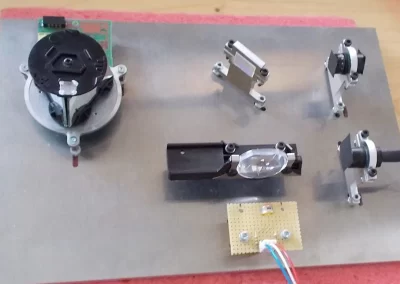

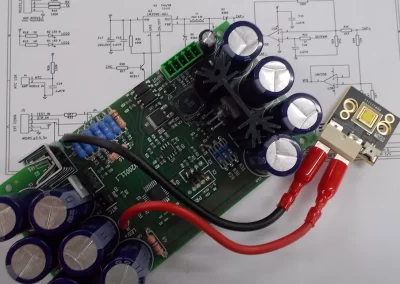

- Designing of an electronic board that reads temperature and sends the measured values to the main controller via serial interface

- Designing the measurement firmware that extracts the average temperature value from the raw data.

Innovative aspects of the project

The project adapts a medical technology to industrial food processes, taking advantage of the characteristics of precision and reliability of the sensors. Actual software technologies allow to extract useful data even in presence of a difficult measurement on uneven and moving masses. The use of adaptive filters and parametric identification models allows to extract from raw data correct measurement values with precision better than 0.5°C.

Results and improvements

The study led to the creation of some prototypes that were then experimentally tested on bread mixer machines in different working conditions. The adopted sensor instantly detects the average temperature of the material present in its visual area (a cone with an angle at the vertex of 10°) at distances of up to a few meters. The sampled values are processed with moving average and adaptive filter that detects the periodicity of fluctuations due to the movement of the dough in the machine. In the case of dough with yeasts it is very important to respect the maximum and minimum temperature limits. Out of these limits the biological action of yeast is affected. The temperature detection system allows the main controller to take appropriate measures such as slowing down of processing to prevent overheating, or stopping and requiring the operator to add ice to cool the mass.

The mechanical assembly of the sensor has been designed to avoid the thermal interference and avoid contact with food in order to meet hygienic requirements. In the case of dusty foods (flour) is planned to use a special protective glass transparent to low temperature thermal infrared radiation (wavelength 1-15um), normally germanium glass.